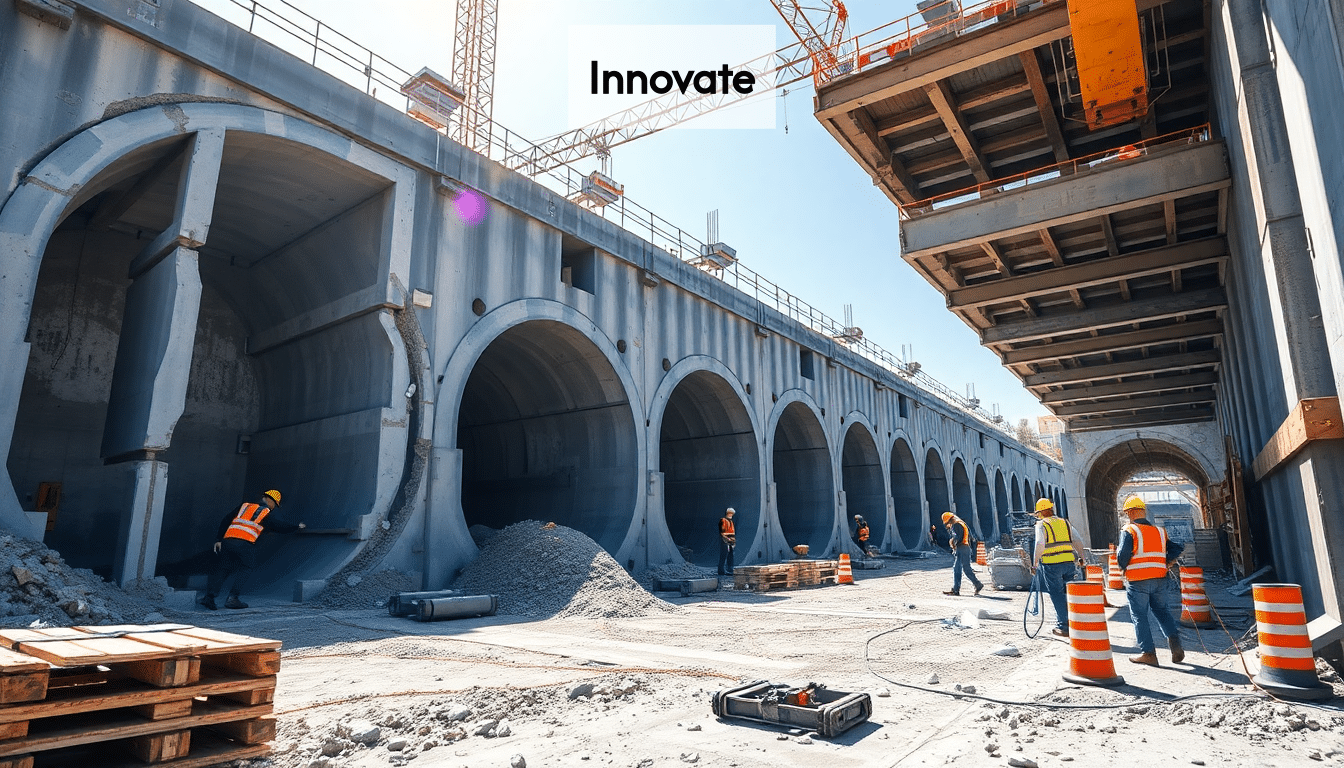

Introduction to Tunnel Form Construction

Welcome to the fascinating world of tunnel form construction! If you’re like me and find yourself captivated by the innovation in building technologies, you’ll appreciate how this method has revolutionized the way we approach concrete structures.

So, what exactly is tunnel form construction? Picture this: a construction technique that allows for the rapid formation of concrete walls and slabs in a single, cohesive step. The beauty of tunnel form construction lies in its efficiency; it’s like a well-oiled machine that churns out robust structures without the need for repetitive formwork. Instead of having different moulds for different parts of your building, a concrete tunnel form allows you to create a whole section at once. The tunnel form system usually consists of prefabricated panels made from durable materials, allowing construction teams to erect entire floors in just a couple of days!

To paint a clearer picture, think about urban apartments or large commercial buildings. With tunnel forming, contractors can create long, uninterrupted spaces that are perfect for modern designs. This method not only speeds up the construction process but also reduces labor costs and minimizes waste.

“Tunnel formwork construction is the ideal solution for high-rise buildings and residential complexes where time and the quality of construction are paramount,” says industry expert and engineer, John Smith. This is because tunnel forms create strong, durable structures that stand the test of time.

In this guide, we’ll dive deeper into the ins and outs of tunnel form construction, examining its advantages and applications. Buckle up, because we’re about to embark on an exciting journey through the concrete tunnels of the construction industry!

Overview of Tunnel Form Systems

As we delve into the specifics of tunnel form systems, it’s important to grasp the components and functionalities that set them apart from traditional construction methods. A tunnel form system, often referred to as tunnel formwork, is a sophisticated assembly that utilizes large, pre-made forms to create structural elements such as walls and slabs simultaneously.

How Tunnel Form Systems Work

The process begins with two sets of concrete tunnel forms that are joined, creating a seamless cavity—think of it like a giant sandwich of concrete! Once the tunnel formwork is set in place, a single concrete pour fills these forms, producing a strong, monolithic structure. This innovative approach allows for several key advantages, which I promise we’ll explore!

Notably, tunnel forming significantly reduces the cycle time for construction. For example, let’s talk about a high-rise residential project; with tunnel form systems, it’s possible to pour an entire floor in just a few days. Imagine how thrilling it is for a construction team to see an entire level crafted in such a short time frame! This efficiency translates not just to faster completion but also to a reduction in labor costs, making it an appealing option for builders and developers.

Key Features of Tunnel Form Systems

One of the standout features of tunnel formwork systems is their adaptability. Whether you’re working on a low- or high-rise building, these systems can be tailored to fit varying design requirements. Additionally, the tunnel shuttering system is designed to accommodate different thicknesses of concrete, ensuring that you can meet local building codes without a hitch.

According to construction expert Jane Doe, “The versatility of tunnel form systems allows us to effectively tackle diverse architectural visions while maximizing structural integrity.”

In our upcoming sections, we will dive deeper into the benefits of concrete tunnel forms, explore practical applications, and highlight real-world examples that showcase just how game-changing this technology is in modern construction.

Advantages of Tunnel Formwork Construction

When it comes to construction techniques, not all methods are created equal. Tunnel formwork construction stands out from the crowd with its unique set of advantages that make it an enticing choice for a variety of projects. As someone who’s dived deep into the world of construction, I can’t help but share how this innovative approach can transform the way we build.

Speed of Construction

First and foremost, let’s talk speed! One of the most significant advantages of using tunnel form systems is their rapid turnaround time. As I mentioned previously, with the ability to pour an entire floor of a building in just a couple of days, you can imagine how beneficial this is for contractors looking to meet tight deadlines. The quick cycle times not only keep the project on track but also allow developers to market new spaces faster, which is crucial in today’s competitive real estate landscape.

Cost Efficiency

Now, who doesn’t love saving a little cash? Tunnel formwork construction dramatically reduces labor costs due to decreased man-hours on-site. Fewer workers are required to assemble and dismantle traditional scaffolding with tunnel forms. According to construction analyst Jake Miller, “By utilizing tunnel form concrete methods, companies can often cut labor costs by as much as 30%.” With lower labor costs and faster project completion, the economics just make sense!

Structural Integrity

Moving on to a critical aspect—structural integrity. Tunnel forms are designed to create a continuous concrete structure, meaning that the walls and floors are monolithic. This not only contributes to the overall strength and durability of the building but also helps in reducing the risk of cracking and structural failures over time. The uniformity of the concrete tunnel helps in enhancing resistance against environmental elements, which is especially beneficial in harsh climates.

Flexible Design Options

Additionally, the flexibility of tunnel form systems cannot be overlooked. They can easily accommodate complex designs, varying thicknesses, and even integrated utility channels in the walls. This adaptability makes it an ideal choice for custom builds where the design demands are slightly out of the ordinary.

Overall, the advantages of tunnel formwork construction are manifold, combining efficiency, cost savings, and structural reliability. It truly represents a leap forward in construction practices and offers promising potential for the future of building. Stay tuned as we dive into real-world applications and success stories that illustrate these benefits in action!

Tunnel Formwork Systems Compared to Traditional Methods

When diving into the world of construction, comparing tunnel formwork systems to traditional methods often feels like pitting a high-speed sports car against a trusty old sedan. Both can get you to the destination, but the performance, efficiency, and experience can differ drastically. Let’s put on our comparative glasses and see how these two approaches stack up against one another!

Speed and Efficiency

One of the most distinguishing factors between tunnel form construction and traditional methods lies in construction speed. With tunnel form systems, an entire floor can be poured in a matter of days thanks to the use of prefabricated forms. In contrast, traditional methods may involve multiple phases of formwork assembly, pouring, curing, and then dismantling, leading to extended timelines. If you’re working with a tight deadline or planning to launch a new residential complex quickly, tunnel forms become a clear winner in terms of efficiency.

Labor Costs and Resource Allocation

Next, let’s consider labor costs. Tunnel forming significantly reduces the manpower required on-site due to its streamlined process. Fewer workers are needed to assemble and dismantle tunnel forms compared to the multiple stages of traditional formwork installation. This translates into cost savings that can be reinvested into other areas of the project. In fact, as I previously noted, companies often experience up to a 30% dip in labor expenses when using concrete tunnel forms. Now, that’s a tempting deal!

Structural Durability

When it comes to the quality of construction, tunnel formwork offers notable advantages. The continuous concrete structure created by tunnel forms enhances the building’s overall durability and reduces potential failure points. Meanwhile, traditional methods often involve multiple joints and seams that could become stress points over time. According to structural engineer Mark Black, “The monolithic nature of tunnel form concrete provides a significant edge in structural resilience and longevity.”

Flexibility in Design

Design flexibility is another area where tunnel formwork shines. While traditional methods can sometimes be limited by the sheer number of forms and scaffolding needed, tunnel systems can be easily adjusted to accommodate a variety of building designs, which makes them ideal for custom projects. Their adaptability ensures a smoother workflow and an overall better fit for modern architectural demands.

Conclusion

In essence, the advantages of tunnel formwork systems are clear when compared to traditional construction methods. They provide speed, cost efficiency, durability, and design flexibility that are hard to beat. While traditional methods certainly still have merit in certain projects, the evolution brought about by tunnel forming has paved the way for smarter, faster, and more sustainable construction techniques. Stick around, as we delve deeper into real-world applications and success stories to show just how impactful tunnel form construction can be!

Applications and Case Studies of Tunnel Form Concrete

As we continue our journey through the realm of tunnel form construction, it’s time to explore its real-world applications and some eye-opening case studies. This construction method is gaining traction in various sectors due to its time-saving and cost-effective nature. Let’s dive into some key applications and noteworthy projects that highlight the prowess of tunnel form concrete!

Residential Buildings

One of the most common applications of tunnel formwork is in residential construction, particularly for high-rise apartment buildings. Take the case of the “Green Heights” complex in a bustling urban center. This project utilized a tunnel form system to erect 300 units in record time—taking only six months to go from foundation to rooftop! The ability to create monolithic walls and floors allowed builders to achieve remarkable energy efficiency while also complying with stringent building codes.

Commercial Developments

Tunnel form systems have also made their mark in the commercial sector. A prime example is the “Metro Plaza” office tower, where tunnel concrete forms were used for a sleek, 15-story structure. The efficiency of the concrete tunnel form resulted in completing the project two months ahead of schedule, and the reduced labor costs made it an attractive choice for the developers. Construction manager Sarah Johnson remarked, “Using tunnel forming was a game-changer for us; it made what typically took a year doable in less than eight months!”

Educational Institutions

Educational buildings are another avenue where tunnel formwork has proven advantageous. The recent construction of the “Tech Valley High School” showcased how an innovative design could be achieved using concrete tunnel forms. The project featured complex architectural details, all while maintaining structural integrity and reducing construction time. By using a tunnel formwork system, the entire building was completed swiftly, bringing the school on schedule for the new academic year.

Industrial Structures

Moreover, tunnel form construction has found its place in the construction of industrial facilities. The “CityWorks” manufacturing plant utilized a concrete tunnel form system to develop its expansive space in record time, allowing for a quick transition to operation. The uniform walls optimized the layout for machinery, enhancing workflow efficiency and safety.

Conclusion

From residential towers to educational institutions and industrial facilities, the applications of tunnel form concrete are diverse and impactful. Case studies reveal that this method not only expedites construction timelines but also fosters innovative designs while ensuring quality control throughout the process. As we continue to explore the evolving landscape of construction, it’s clear that tunnel formwork systems are paving the way for a more efficient and sustainable future in building practices.

Future Trends in Tunnel Form Construction

As we stand at the crossroads of innovation and construction, the future of tunnel form construction looks brighter than ever! With an industry that’s continuously evolving to meet the demands of modern architecture, we can anticipate some exciting trends that are likely to shape the way we build in the coming years. Get ready to delve into the possibilities that lie ahead!

Technological Integration

First and foremost, the integration of advanced technologies is poised to revolutionize tunnel formwork systems. The use of Building Information Modeling (BIM) is already gaining traction, allowing architects and engineers to create highly detailed 3D models before construction begins. This can enhance accuracy and help in resolving potential problems even before the first concrete pour. Imagine a bustling construction site where drones are used to survey progress in real-time, allowing for quicker adjustments and improved workflow!

Sustainable Practices

Another prominent trend is the emphasis on sustainability within tunnel form construction. With growing awareness around environmental issues, there is an increasing push for greener building practices. Concrete tunnel forms can now be designed to incorporate recycled materials, and the ability to create energy-efficient structures makes them a suitable choice in the age of eco-consciousness. Innovations in materials, such as lighter and more sustainable concrete compositions, are emerging, adding to the appeal of tunnel forming.

Modular Construction and Prefabrication

The surge in modular construction is also shifting the landscape. As the construction industry embraces prefabrication, tunnel form systems will likely adapt to these trends. This means we might see more components manufactured off-site and assembled on-site, speeding up project timelines even further. Think of it as cooking with a meal kit—everything is prepared ahead of time, and all you have to do is put it together!

Enhanced Safety Measures

Moreover, safety continues to be paramount in construction. Technology that monitors site conditions, worker activity, and structural integrity in real-time will become crucial. With improvements in scaffold and form safety, tunnel form systems can significantly benefit as these enhancements are applied, leading to safer working environments.

Conclusion

As we peer into the crystal ball of tunnel form construction, the blend of advanced technology, sustainable practices, modularity, and safety improvements is set to forge a path towards a more innovative and efficient industry. With these trends in play, the potential for tunnel form systems holds tremendous promise, assuring us that the future of construction is not just bright, but also built to last! Stay tuned, as we’ll explore each of these trends in more detail in upcoming sections.

Frequently Asked Questions

What is tunnel form construction?

Tunnel form construction is a building method that uses large, prefabricated forms to create concrete walls and slabs simultaneously, allowing for the rapid and efficient construction of structures such as high-rise buildings and residential complexes.

What are the advantages of using tunnel formwork?

Tunnel formwork offers several advantages, including reduced construction time, lower labor costs, enhanced structural integrity, and increased design flexibility compared to traditional construction methods.

How does tunnel formwork improve construction speed?

Tunnel form systems allow for the pouring of entire floors within a few days, significantly reducing cycle times in construction projects and enabling faster progress in completing buildings.

In what types of projects is tunnel form construction commonly used?

Tunnel form construction is commonly used in residential buildings, commercial developments, educational institutions, and industrial structures due to its efficiency and ability to conform to various design needs.

Elevate Your Career in Tunnel Form Construction with Amundson Group!

Are you captivated by the efficiency and innovation of tunnel form construction, just like the experts highlighted in our informative guide? You might be one of the talented professionals who can harness this construction method’s potential, contributing to high-rise buildings and revolutionary projects. However, finding the right opportunity in the bustling construction industry can pose its own set of challenges.

🔑 Key Pain Points:

- Navigating a Competitive Market: With the construction sector evolving rapidly, identifying the best-fit roles that align with your specialized skills can feel overwhelming.

- Quality Connections: It’s not just about what you know, but who you know! Developing a robust network within sectors like heavy civil, multi-family housing, and wastewater management is crucial.

At Amundson Group, we specialize in connecting skilled professionals like you with companies seeking your unique talents. Our user-friendly job search platform showcases a wealth of opportunities tailored to your expertise and the industry’s evolving demands. Plus, our strategic partnerships with industry leaders position us as your go-to resource in landing your dream job.

🚀 Ready to seize the moment? Embrace the dynamism of tunnel form construction by exploring our available positions now! Visit us at https://amundsongroup.com and take the first step towards transforming your career. The construction landscape is changing—don’t let this chance pass you by!

Your future in construction starts here. Act NOW!