Introduction to Construction Tunnel

Hey there, fellow infrastructure enthusiasts! Have you ever driven through a mountain or underneath a river and thought, “Wow, how on earth did they build this?” Well, I’m here to take you on a fascinating journey into the world of construction tunnels!

Constructing tunnels is honestly one of the most impressive feats of civil engineering we humans have accomplished. Whether we’re talking about underground tunnel construction beneath bustling cities or the construction of tunnels through massive mountain ranges, these projects represent the perfect marriage of ambition, engineering prowess, and raw determination.

As someone who’s been obsessed with tunnel constructions for years (yes, I’m that person at parties), I can tell you that the method of tunnel construction has evolved dramatically over time. From the dangerous hand-digging techniques of the past to today’s massive tunnel boring machines (affectionately called “mechanical moles” by us nerds in the industry), tunnel building continues to push the boundaries of what’s possible.

“Tunnels are the ultimate challenge for civil engineers because they combine almost every aspect of the discipline – from soil mechanics to structural design to water management,” explains Dr. Elena Rodriguez, a leading expert in tunnelling construction.

In this article, I’ll walk you through the fascinating techniques, impressive benefits, and yes, the daunting challenges that come with constructing a tunnel. So buckle up – we’re about to go underground!

What is Tunnel Construction?

So what exactly is tunnel construction? In its simplest form, it’s the process of creating a passage through or under an obstacle. But let me tell you, there’s nothing simple about it!

Construction of underground tunnels involves excavating soil and rock to create a hollow passageway that can be used for transportation, utility infrastructure, or even military purposes. As someone who’s stood inside these magnificent hollow spaces during construction, I can attest that it feels like you’re witnessing human ingenuity at its finest.

Tunnel constructions vary widely depending on their purpose and location. Transportation tunnels like those for subways, cars, or trains make up the majority of what tunnel constructors build today. But we also create utility tunnels for water, sewage, or electrical lines, mining tunnels to access valuable resources, and even scientific tunnels (like the Large Hadron Collider – how cool is that?).

“The definition of tunnel work might seem straightforward, but each project presents unique geological, environmental, and engineering challenges,” says Mark Stevenson, who’s spent 30 years as a tunnel engineer. “No two tunnels are ever the same.”

What fascinates me about constructing tunnels is how it combines ancient knowledge with cutting-edge technology. Some of the fundamental principles of how tunnels are constructed haven’t changed much since ancient Romans built aqueducts, but today’s tools and techniques would leave those early engineers absolutely speechless!

The construction of a tunnel is like performing surgery on the earth itself – it requires precision, planning, and respect for the natural forces you’re working with. And just like any good surgery, the best tunnel job is one where you’d never know someone had been there at all… except for that convenient passage that wasn’t there before!

The Importance of Underground Tunnel Construction

Let me tell you something – underground tunnel construction isn’t just cool (though it definitely is!) – it’s absolutely essential for modern civilization. When I think about the most transformative infrastructure projects of the last century, tunnels are right at the top of the list.

Why are we so obsessed with digging holes through things? Well, the construction of tunnels solves some of our biggest urban and transportation challenges. In densely populated cities where space is at a premium, going underground is often the only viable option for expanding infrastructure. That’s why underground tunnels construction has boomed in metropolitan areas worldwide.

“The ability to construct efficient underground passages has become a defining factor in a city’s economic competitiveness and quality of life,” explains urban planner Dr. Janelle Wong. “Cities that master tunnelling construction gain a significant advantage in addressing congestion and pollution.”

Think about it – every time you’ve avoided sitting in gridlocked traffic because you could zip through a tunnel, you’ve experienced this benefit firsthand! The construction of underground tunnels also preserves valuable surface space for parks, buildings, and other public uses. I remember visiting Boston after their famous “Big Dig” project (one of the most ambitious tunnel construction projects in US history), and the transformation of the city was breathtaking.

Beyond transportation, constructing tunnels for utilities keeps essential services protected from weather events and creates easier maintenance access. And let’s not forget the environmental benefits – tunnel building can reduce the fragmentation of habitats and ecosystems that roads and railways might otherwise cause.

So next time you’re driving through a mountain or riding a subway under a river, take a moment to appreciate the incredible construction tunnel engineering that’s making your journey possible!

Key Techniques in the Construction of Underground Tunnels

Let’s dig into the nitty-gritty (pun absolutely intended) of how tunnels are constructed! As someone who’s watched these engineering marvels take shape, I can tell you that tunnel construction techniques have come a long way from just grabbing a shovel and hoping for the best.

Cut and Cover Method

The simplest method of tunnel construction is probably the cut and cover technique. It’s exactly what it sounds like – we dig a trench, build the tunnel structure, and then cover it back up. I’ve seen this used extensively in shallow underground tunnel construction projects in urban areas. It’s like making a sandwich, if the bread was earth and the filling was a massive concrete tunnel!

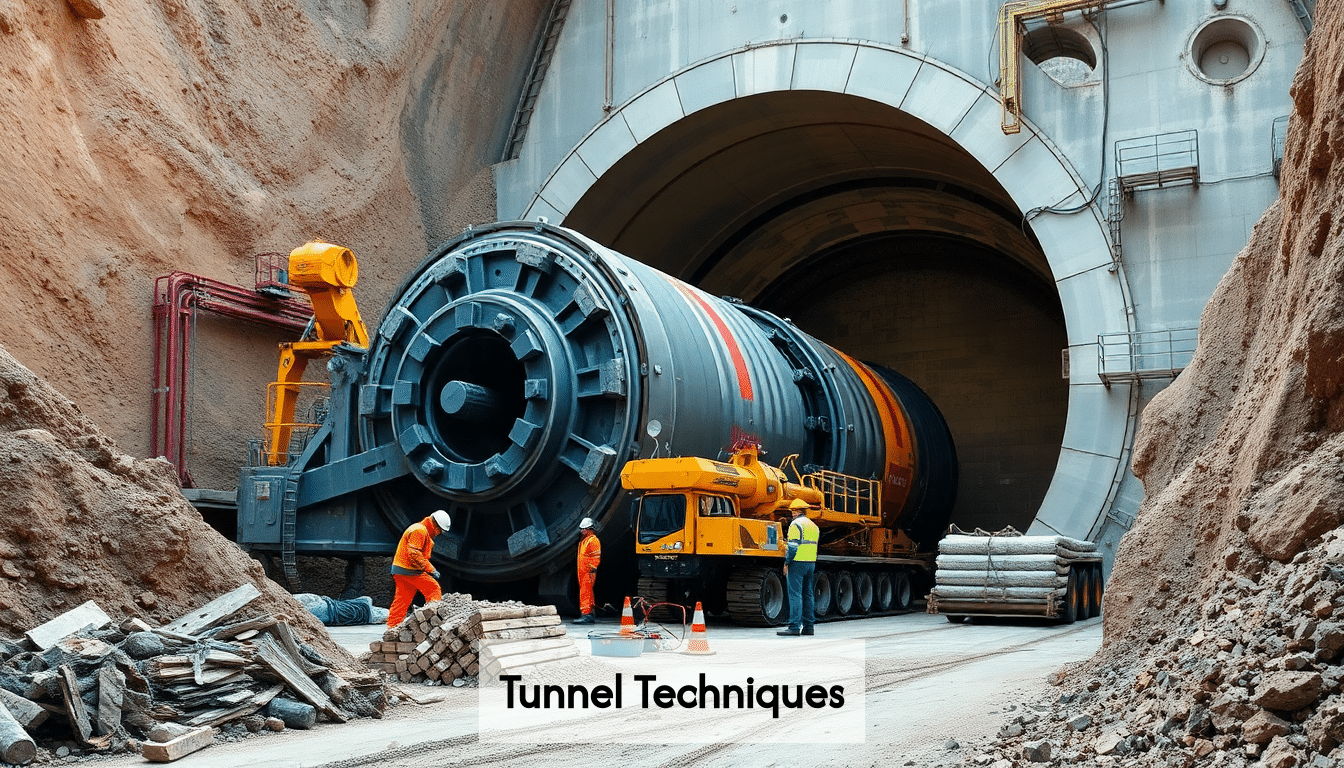

Tunnel Boring Machines (TBMs)

My personal favorites in constructing tunnels are the massive TBMs – these mechanical beasts are essentially giant drilling machines that can chew through almost anything. Some of these machines used in construction of a tunnel are so large you could drive a car through them! They’re nicknamed “moles” in the industry, but that’s like calling a T-Rex a lizard – bit of an understatement!

New Austrian Tunnelling Method (NATM)

The NATM is another fascinating approach to construction of tunnels that uses the surrounding rock mass as a structural component. “What makes NATM particularly valuable in tunnel constructions is its adaptability to varying geological conditions,” explains Dr. Hans Müller, one of the pioneers of this technique. “It allows tunnel constructors to respond to what the mountain tells them.”

Immersed Tube Method

For underwater passages, tunnelling construction often employs the immersed tube method. Huge concrete sections are prefabricated, floated to the site, sunk into a prepared trench, and connected underwater. I once watched this process for a harbor tunnel building project and it was like watching an underwater ballet of massive concrete sections!

Each of these construction tunnel techniques has its place depending on geology, location, budget, and purpose. The science behind choosing the right method is almost as fascinating as the tunnel work itself!

Common Methods of Tunnel Construction

Having covered some key techniques, let’s break down the most common methods of tunnel construction that you might encounter in different projects around the world. Trust me, the variety in tunnel construction approaches makes this field endlessly fascinating!

Drill and Blast Method

This is the old-school approach to constructing tunnels – drilling holes in the rock face, filling them with explosives, detonating, clearing the debris, and repeating. I’ve witnessed this method in action during mountain tunnel constructions, and let me tell you, it’s both terrifying and thrilling! Despite being one of the oldest techniques in construction of tunnels, it remains incredibly effective for hard rock conditions where TBMs might struggle.

Sequential Excavation Method (SEM)

A more modern approach to underground tunnels construction is SEM, which involves carefully excavating small sections at a time while immediately installing support systems. I love how SEM showcases the artistry in construction tunneling – it’s less brute force and more strategic chess game with geology.

“The beauty of SEM in underground tunnel construction is its flexibility,” says Patricia Gonzalez, a veteran tunnel engineer. “We can adjust our approach meter by meter as ground conditions change, which is often essential in urban environments.”

Pipe Jacking/Microtunneling

For smaller diameter tunnels, especially in urban utility tunnel building, pipe jacking has revolutionized how we work. This technique involves pushing (or “jacking”) pipes through the ground from a launch shaft while excavation occurs at the front end. As someone who’s spent time in cramped utility tunnels, I’m personally grateful for any method of tunnel construction that minimizes the need for humans to squeeze into tiny spaces!

Immersed Tunneling

For crossing bodies of water, constructing a tunnel often means creating huge concrete sections on land, floating them to location, sinking them into a prepared trench, and connecting them underwater. It’s like assembling a massive underwater LEGO set, and it never ceases to amaze me how tunnel constructors manage this complex dance of enormous concrete elements!

Challenges Faced in the Construction of Tunnels

Let’s get real for a minute – constructing tunnels might be fascinating, but it’s also one of the most challenging endeavors in civil engineering. Trust me, I’ve seen projects where even the most experienced tunnel constructors were scratching their heads in puzzlement!

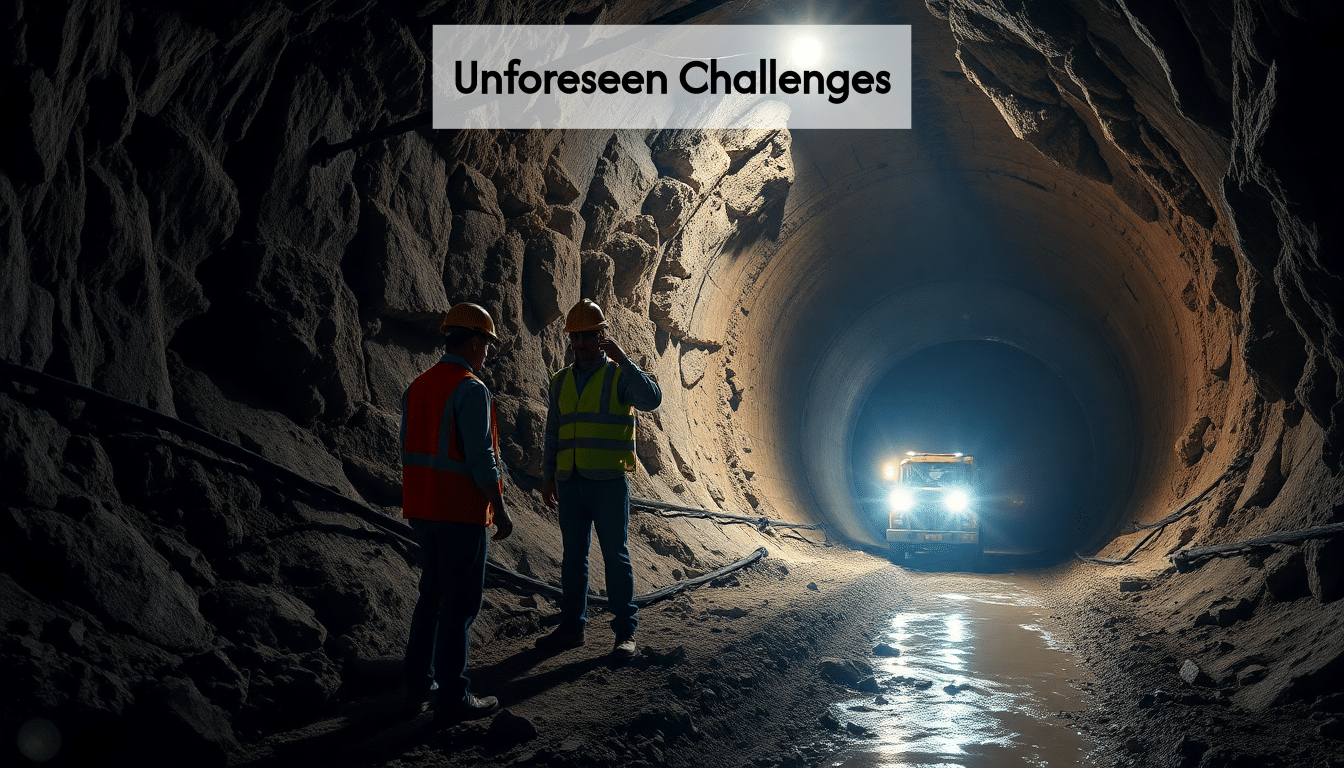

Geological Surprises

The biggest headache in underground tunnel construction is that Mother Nature loves to throw curveballs. Despite all our fancy ground-penetrating radar and soil testing, you never truly know what’s in that rock until you start digging. I’ve heard countless stories of tunnel constructions hitting unexpected fault lines, water pockets, or rock formations that weren’t on any geological map.

“In construction of a tunnel, the ground is always the boss,” says veteran engineer Marco Sanchez. “I’ve seen projects where a single unexpected geological formation added months to the timeline and millions to the budget.”

Water Management

Water and tunnelling construction have a complicated relationship – like that couple that shouldn’t be together but somehow always ends up in the same room. Groundwater can flood excavations, create unstable conditions, and generally make everyone’s life miserable. Managing water infiltration is often one of the most complex aspects of construction of tunnels.

Safety Concerns

I don’t want to sound dramatic, but tunnel work can be dangerous business. The risk of cave-ins, flooding, lack of oxygen, and other hazards means safety protocols in underground tunnels construction are incredibly stringent. Having visited active construction sites, I’ve experienced firsthand the extensive safety measures required – from constant air quality monitoring to elaborate emergency evacuation plans.

Urban Disruption

When constructing a tunnel in an urban environment, you’re essentially performing major surgery underneath someone’s home or business. Minimizing disruption to surface activities while construction tunneling proceeds below is a delicate balancing act. Nobody wants to be the engineer whose project caused a historic building to suddenly develop a fascinating new lean!

Technical Complexities

From ventilation systems to fire safety, the technical requirements of modern tunnel building are mind-boggling. Each method of tunnel construction comes with its own set of engineering challenges that require specialized expertise to overcome. It’s like trying to build a self-contained underground city – which is basically what modern tunnels are!

Safety Measures in Construction Tunneling

I won’t sugarcoat it – construction tunneling is inherently risky business. When you’re blasting through rock and excavating beneath hundreds of feet of earth, safety isn’t just a priority—it’s an absolute necessity. During my visits to active tunnel construction sites, I’ve been amazed by the comprehensive safety systems in place.

Risk Assessment and Planning

Every successful construction of tunnels begins with thorough risk assessment. Teams analyze potential hazards specific to the geology, depth, and environment before the first shovel hits the ground. I remember chatting with a tunnel building project manager who showed me a risk assessment document that was literally thicker than some of my college textbooks!

“The most crucial safety measure in underground tunnel construction happens before we even begin digging,” explains safety coordinator Elaine Thompson. “We map out every conceivable risk scenario and develop response protocols for each one. In this business, paranoia is actually a professional asset.”

Air Quality Monitoring

One invisible yet deadly danger in constructing tunnels is poor air quality. Modern tunnel constructions employ continuous monitoring systems for oxygen levels, toxic gases, and particulates. I once watched engineers scramble to address a minor methane buildup detected by sensors during a construction of underground tunnels project—their rapid response potentially prevented a dangerous situation.

Ground Support Systems

Preventing cave-ins is obviously paramount in tunnelling construction. This involves installing rock bolts, wire mesh, shotcrete (sprayed concrete), and steel arches as the excavation progresses. The science behind determining adequate support during construction of a tunnel is fascinating and critically important.

Emergency Protocols

Every underground tunnels construction site I’ve visited has extensive emergency response plans. This includes rescue chambers with independent air supplies, multiple communication systems, and evacuation routes. Tunnel constructors regularly conduct drills to ensure everyone knows exactly what to do if something goes wrong.

Specialized Training

Workers involved in tunnel work receive specialized training far beyond standard construction safety. From operating under compressed air conditions to handling explosives safely, the skill set required for those working in constructing a tunnel is impressive and highly specialized.

While these safety measures add time and cost to projects, they’re absolutely non-negotiable in modern construction tunneling. And thank goodness for that!

The Future of Tunnel Work: Trends in Tunnels Construction

Let me put on my future-gazing hard hat for a moment! The world of tunnels construction is evolving at a pace that would make those early tunnel pioneers’ heads spin. As someone who geeks out about infrastructure innovations, I’m genuinely excited about where construction tunneling is headed.

Automation and Robotics

The future of tunnel work is increasingly automated. Modern Tunnel Boring Machines (TBMs) already incorporate impressive automation, but we’re moving toward systems where robots handle the most dangerous aspects of underground tunnel construction. I recently saw a demonstration of robotic systems for installing support elements that had me practically jumping with excitement – fewer humans in dangerous positions means safer construction of tunnels!

“We’re approaching a turning point where AI-guided systems will transform how we approach constructing tunnels,” says Dr. Wei Chang, robotics expert at the International Tunneling Association. “The next generation of TBMs will adapt to geological conditions in real-time without human intervention.”

Sustainable Tunneling

Green tunneling isn’t just a buzzword – it’s transforming how tunnel constructors approach projects. From electric-powered equipment to using excavated materials in concrete production, construction of underground tunnels is becoming dramatically more sustainable. Some projects are even integrating geothermal energy collection into tunnel linings – how cool is that? The tunnel actually produces energy while serving its primary purpose!

Digital Twins and Simulation

Perhaps the most revolutionary trend in tunnel building is the creation of comprehensive digital twins – virtual replicas of tunnels that model every aspect of both construction and operation. I’ve played with some of these simulation systems, and they’re mind-blowing! They allow tunnel constructions teams to identify potential issues before they become actual problems.

Hyperloop and Beyond

The most exciting frontier in construction of a tunnel might be the integration with next-generation transportation systems like Hyperloop. These vacuum tube transport systems require tunnels with unprecedented precision and different specifications than traditional tunnels. When I think about the future of underground tunnels construction, I get goosebumps imagining networks of high-speed, low-energy transport connecting our cities underneath the congested surface world!

These innovations aren’t just making tunnelling construction faster and cheaper – they’re expanding what’s possible underground. The tunnels of tomorrow will be smarter, more sustainable, and might just revolutionize how we think about infrastructure.

Conclusion: The Role of Tunnel Constructors in Infrastructure Development

As we’ve tunneled through this deep dive into the world of underground construction (pun absolutely intended), I hope you’ve gained a new appreciation for the remarkable work that goes into constructing a tunnel. These aren’t just holes in the ground – they’re engineering marvels that connect communities, power economies, and solve seemingly impossible transportation challenges.

The construction of tunnels represents humanity at its most ambitious and ingenious. When I think about the professionals behind these projects – the engineers, geologists, construction workers, and safety specialists – I’m in awe of their collective expertise. These tunnel constructors are literally reshaping our world from beneath the surface, often without most of us even noticing their work until we’re driving through their completed masterpieces.

“What makes tunnel construction so unique in civil engineering is that it combines technical precision with a deep respect for natural forces,” reflects Maria Gonzalez, who’s overseen major underground tunnels construction on three continents. “We’re not conquering nature so much as negotiating with it.”

The future of infrastructure development will increasingly depend on excellence in tunnelling construction. As urban centers become more densely populated and surface space grows more precious, underground tunnel construction offers solutions that simply aren’t possible above ground. From transit systems to water management to utility corridors, the construction of underground tunnels will play a vital role in building resilient, sustainable cities.

So the next time you zoom through a mountain in your car or ride a subway under a river, take a moment to appreciate the remarkable tunnel work that made your journey possible. And maybe, just maybe, you’ll start to see the world beneath your feet a little differently – as a frontier of human achievement that continues to expand with each new tunnel building project.

I hope this exploration of construction tunnels has been as fascinating for you to read as it was for me to write. Keep looking up, but don’t forget to appreciate what’s underground!

Frequently Asked Questions

What are the main methods of tunnel construction?

The main methods of tunnel construction include the cut and cover method, tunnel boring machines (TBMs), the New Austrian Tunnelling Method (NATM), and the immersed tube method. Each method is chosen based on geological conditions and project requirements.

Why is underground tunnel construction important?

Underground tunnel construction is crucial for expanding infrastructure in densely populated areas, reducing surface congestion, and preserving surface space for public use. It also protects utilities and minimizes environmental impact compared to surface alternatives.

What are the challenges faced during tunnel construction?

The challenges in tunnel construction include geological surprises, groundwater management, safety risks, urban disruption, and technical complexities. Each of these factors can impact timelines and costs significantly.

What safety measures are implemented in tunnel construction?

Safety measures in tunnel construction involve thorough risk assessments, air quality monitoring, ground support systems, emergency protocols, and specialized training for workers. These protocols are essential to ensure the safety of personnel and the integrity of the tunnel during construction.

Unlock Your Future in Tunnel Construction!

Have you been captivated by the incredible challenges and innovative techniques of tunnel construction discussed in the article? Whether it’s managing geological surprises or navigating the complexities of urban disruption, the construction industry thrives on skilled professionals who can tackle these real-life challenges head-on. As the world increasingly relies on sophisticated underground infrastructure, the demand for talented individuals in this field is at an all-time high.

!

Don’t let your expertise go unnoticed! At Amundson Group, we specialize in connecting dedicated professionals like you with leading opportunities across heavy civil, commercial, and site development sectors. Our extensive network and personalized talent acquisition solutions mean you can trust us to match your unique skills with the best positions available. Why wait? Dive into the exciting world of tunnel construction today! Start exploring potential job placements now and shape the future of infrastructure with your expertise.